Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

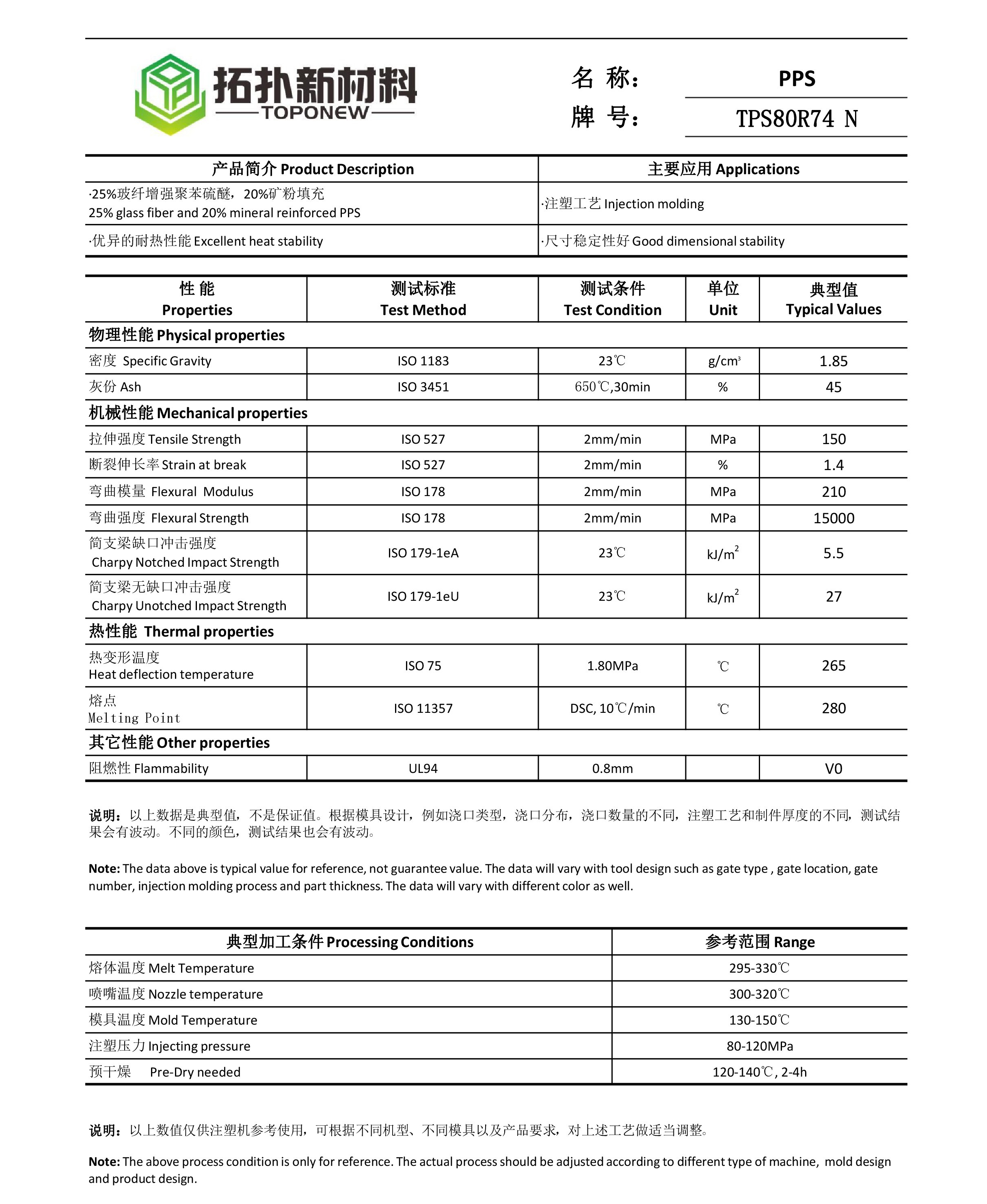

PPS GF25 MF20 TPS80R74N

Glass Filled: 25%

Mineral Filled: 20%

(Custom materials available according to your Technical Data Sheet)

- Detalle del producto

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PPS GF25 MF20 TPS80R74N

Polyphenylene Sulfide (PPS) GF25 MF20 Granules are a type of reinforced engineering plastic material. PPS is renowned for its outstanding properties, such as high heat resistance, excellent mechanical strength, and exceptional chemical resistance.

The "GF25" in its name stands for 25% glass fiber content, which enhances the material's stiffness, strength, and dimensional stability. This reinforcement makes it suitable for applications requiring strong and rigid parts.

The "MF20" designation refers to a mineral filler (such as mica) added to the PPS matrix to further enhance its mechanical and thermal properties. The addition of mineral fillers helps improve the material's dimensional stability, creep resistance, and flame retardancy.

PPS GF25 MF20 granules find applications in various industries, including automotive, electrical and electronics, industrial equipment, and more. They can be used for manufacturing components such as housings, connectors, gears, and other parts that require high strength, durability, and resistance to heat and chemicals.

Overall, PPS GF25 MF20 granules are a versatile and high-performance material choice in engineering applications where exceptional mechanical properties and resistance to harsh environments are essential.

In chemistry, PPS stands for Polyphenylene Sulfide. PPS is a high-performance engineering thermoplastic that belongs to the class of polymeric organic compounds. It is a semi-crystalline polymer known for its exceptional thermal, chemical, and mechanical properties.

Here are some key characteristics of Polyphenylene Sulfide (PPS):

-

High Temperature Resistance: PPS exhibits excellent heat resistance, with a high melting point and the ability to maintain its mechanical properties at elevated temperatures. It can typically withstand continuous use at temperatures up to 200-240°C (392-464°F).

-

Chemical Resistance: PPS has good resistance to a wide range of chemicals, solvents, acids, and bases. It is resistant to many organic solvents and is stable in acidic and alkaline environments.

-

Flame Retardant: PPS is inherently flame retardant and self-extinguishing, making it suitable for applications where fire safety is a concern.

-

Mechanical Properties: PPS offers excellent mechanical properties, including high stiffness, dimensional stability, and creep resistance. It has good strength and impact resistance.

-

Electrical Insulating Properties: PPS is known for its excellent electrical insulating properties, making it suitable for electrical and electronics applications.

-

Dimensional Stability: PPS has low moisture absorption, which helps maintain its dimensional stability under varying environmental conditions.

-

Chemical Inertness: PPS is chemically inert to many substances, resulting in good resistance to environmental stress cracking.

PPS is commonly used in a variety of industries, including automotive, aerospace, electrical and electronics, industrial, and chemical processing, where high temperature resistance, chemical resistance, and mechanical strength are required. It is used in applications such as automotive components, electrical connectors, pump and valve parts, filters, and housings.

What is PPS composite?

PPS (Polyphenylene Sulfide) composite refers to a material that combines PPS resin with other substances to enhance its properties or tailor it for specific applications. PPS itself is a high-performance thermoplastic known for its exceptional chemical resistance, thermal stability, and mechanical strength, making it suitable for demanding environments such as automotive, electrical, and industrial applications.

PPS composites can include various additives or reinforcements to further improve certain characteristics. For example, glass fibers may be added to enhance strength and stiffness, while mineral fillers can improve dimensional stability and reduce shrinkage. Additionally, PPS composites may incorporate additives for flame retardancy, lubrication, or other specific requirements based on the intended use of the material.

Overall, PPS composites offer a balance of high performance, durability, and versatility, making them valuable for a wide range of applications where reliability and longevity are crucial.

Download

-

PPS TPS80R74N.pdf

Download PPS TPS80R74N.pdf